Product Overview

Hiyka's Gamma Phase Aluminum Oxide is a versatile, high-performance nanomaterial characterized by its exceptional surface area, porosity, and catalytic efficiency. Engineered for optimal performance, our gamma aluminum oxide is an ideal choice for a wide range of applications, including catalysis, adsorption processes, and as a support material for active phases in industrial chemical reactions. This material is specifically designed to meet the demands of industries seeking advanced solutions for environmental purification, chemical synthesis, and energy conversion processes.

Key factor

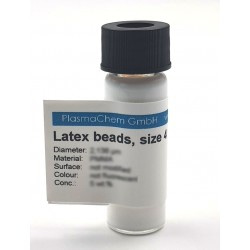

- High Surface Area: Offers a large surface area, essential for catalytic applications and adsorption processes.

- Enhanced Porosity: Features a highly porous structure, facilitating the diffusion of reactants and products during catalytic reactions.

- Catalytic Activity: Exhibits excellent catalytic properties, making it suitable for a variety of chemical synthesis and environmental remediation applications.

- Thermal Stability: Maintains structural integrity and performance under high-temperature conditions.

- Chemical Versatility: Compatible with a wide range of chemical reactions, serving as an effective support material for catalytic agents.

Applications

- Catalysis: Utilized as a catalyst or catalyst support in the synthesis of fine chemicals, petrochemical processing, and environmental catalysts for pollution control.

- Adsorption: Effective in adsorption processes for removing pollutants from water and air, including heavy metals and volatile organic compounds (VOCs).

- Chemical Synthesis: Plays a critical role in various chemical synthesis processes, enhancing reaction efficiency and selectivity.

- Energy Conversion: Applied in materials for energy conversion devices, including fuel cells and batteries, to improve efficiency and durability.

- Refractory Materials: Used in the production of refractory materials due to its high temperature resistance and mechanical strength.

Advantages

- Enhanced Performance: Improves the efficiency and effectiveness of catalytic and adsorption processes.

- Economic Efficiency: Offers cost-effective solutions for industrial processes, reducing the need for precious metal catalysts.

- Environmental Impact: Supports environmental sustainability efforts through its role in pollution control and clean energy technologies.

- Reliability and Durability: Provides long-lasting performance and stability, reducing the need for frequent replacement or regeneration.

- Customizability: Suitable for a variety of applications, enabling customization to specific process requirements.

References

- Evaluation of alpha and gamma aluminum oxide nanoparticle accumulation, toxicity, and depuration in Artemia salina larvae, M Ates, V Demir, Z Arslan, J Daniels… - Environmental …, 2015 - Wiley Online Library

Analysis of crystalline phase aluminum oxide particles from solid propellant exhausts

KM Dill, RA Reed, VS Calia, RJ Schulz - Journal of Propulsion and …, 1990 - arc.aiaa.orgSolvent-free hydrothermal synthesis of gamma-aluminum oxide nanoparticles with selective adsorption of Congo red,H Zhang, Y Ruan, Y Feng, M Su, Z Diao, D Chen… - Journal of colloid and …, 2019 - Elsevier