Product Overview

Our Anti-Corrosion and Thermally Conductive Coating for Copper, formulated with a solvent-based epoxy system, represents a dual-function solution engineered to protect copper surfaces from environmental degradation while improving their ability to manage heat. This innovative coating is specifically designed for applications where copper's thermal conductivity is critical, but its susceptibility to corrosion could compromise performance and longevity.

Key factor

- Dual-Function Protection: Offers superior protection against corrosion while enhancing the thermal conductivity of copper surfaces, ensuring optimal performance in thermal management applications.

- High Durability: The solvent-based epoxy formulation provides a robust, durable coating that adheres strongly to copper, withstanding harsh environmental conditions.

- Enhanced Thermal Conductivity: Designed to not impede, but rather to enhance, the natural thermal conductivity of copper, facilitating efficient heat dissipation.

- Easy Application: Can be applied to copper surfaces using conventional coating methods, allowing for seamless integration into manufacturing and maintenance processes.

- Environmentally Resistant: Effectively protects against moisture, salts, and other corrosive agents, ensuring the coated copper maintains its integrity and functionality.

Applications

- Heat Exchangers and Radiators: Enhances the efficiency and longevity of copper components used in cooling systems.

- Electronics and Electrical Systems: Ideal for printed circuit boards (PCBs) and other electronic components where thermal management and corrosion resistance are critical.

- Automotive Cooling Systems: Provides corrosion protection and thermal conductivity for copper parts used in automotive radiators and cooling systems.

- Renewable Energy Systems: Supports the durability and performance of copper components in solar thermal panels and other renewable energy applications.

- Industrial Machinery: Protects and enhances the thermal efficiency of copper parts in industrial machinery and equipment subject to high temperatures and corrosive environments.

Advantages

- Improved Equipment Efficiency: By enhancing thermal conductivity, the coating supports the efficient operation of heat exchangers, cooling systems, and other thermal equipment.

- Extended Service Life: Protects copper components from corrosion, significantly extending their operational lifespan and reducing the need for frequent replacements.

- Cost Savings: Minimizes maintenance and operational costs by preventing corrosion-related failures and enhancing thermal performance.

- Versatile Application: Ideal for a wide range of industries, including HVAC, automotive, electronics, and energy sectors, where copper is commonly used for its thermal properties.

- Performance Reliability: Ensures consistent performance and reliability of copper components in various environmental conditions, supporting the demands of advanced technology applications.

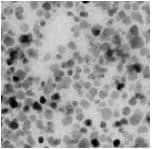

Why HIYKA

Warrior Anticorrosion Thermally Conductive ( Solvent based for Quick drying ) Coating is far superior to other available coatings in market as the other coatings may provide corrosion resistance but due to the poor conductivity of these coatings ( as they are not thermally conductive, where as copper is highly thermally conductive ) so applying these coatings on copper pipers will significantly reduce your AC performance and your electricity bill will sky rocket , where as our Coatings have been added with Nanomaterials which have equivalent thermal conductivity as copper and also our coating is having excellent adhesion with copper , thus making it really effective from all aspects not just anti corrosion .