Product Overview

Introducing our innovative Anti-Corrosion and Thermally Conductive Coating, a solvent-based solution meticulously engineered for copper surfaces. This specialized coating is designed to address the dual challenges faced by copper components: the need for robust corrosion resistance and the demand for maintaining or enhancing thermal conductivity.

Key factor

- Superior Corrosion Resistance: Offers exceptional protection against environmental factors that cause corrosion in copper, ensuring the longevity and integrity of copper components.

- Enhanced Thermal Conductivity: Specifically formulated to not only preserve but potentially enhance the natural thermal conductivity of copper, facilitating efficient heat dissipation.

- Solvent-Based Formula: Provides strong adhesion and durability, ensuring that the coating remains effective even under harsh conditions and over extended periods.

- Versatility in Application: Suitable for a wide array of copper-based applications, including electronics, cooling systems, and industrial machinery.

- Ease of Use: Can be applied through standard coating techniques, making it convenient for both new manufacturing and maintenance applications.

Applications

- Electronics and PCBs: Ideal for protecting printed circuit boards and electronic components where thermal management and corrosion resistance are critical.

- Cooling Systems: Enhances the performance and longevity of copper parts used in cooling systems, including radiators and heat exchangers.

- Automotive Components: Protects copper components within automotive electrical and cooling systems from corrosion and thermal degradation.

- Renewable Energy Systems: Suitable for solar thermal collectors and other renewable energy applications that utilize copper for its excellent thermal conductivity.

- Industrial Machinery: Offers protection for copper components in machinery and equipment exposed to corrosive environments or requiring efficient heat dissipation.

Advantages

- Prolonged Component Life: By preventing corrosion, the coating significantly extends the usable life of copper parts, reducing the need for frequent replacements.

- Maintained or Enhanced Performance: Ensures optimal thermal performance of copper components, crucial for applications requiring efficient heat management.

- Cost-Effective Protection: Offers a long-term, cost-saving solution by protecting valuable copper components against corrosion and thermal inefficiency.

- Industry-Wide Application: Its properties make it an ideal choice for various sectors, including electronics, automotive, aerospace, and renewable energy.

- Improved Reliability: Enhances the reliability of copper components, contributing to the overall performance and durability of the systems they are part of.

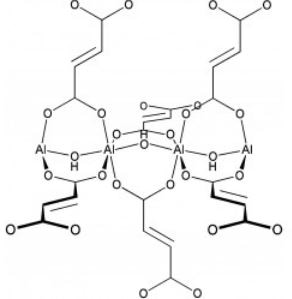

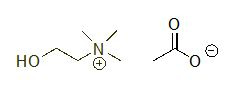

Why HIYKA

Warrior Anticorrosion Thermally Conductive ( Solvent based for Quick drying ) Coating is far superior to other available coatings in market as the other coatings may provide corrosion resistance but due to the poor conductivity of these coatings ( as they are not thermally conductive, where as copper is highly thermally conductive ) so applying these coatings on copper pipers will significantly reduce your AC performance and your electricity bill will sky rocket , where as our Coatings have been added with Nanomaterials which have equivalent thermal conductivity as copper and also our coating is having excellent adhesion with copper , thus making it really effective from all aspects not just anti corrosion .