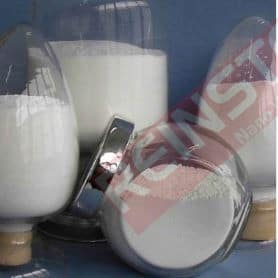

Product Overview

Our CNTs LLDPE Masterbatch is designed to revolutionize the plastics industry by integrating the exceptional properties of carbon nanotubes (CNTs) with the versatility of linear low-density polyethylene (LLDPE). This masterbatch offers an unparalleled solution for enhancing the mechanical, thermal, and electrical properties of LLDPE-based products. Ideal for applications requiring improved durability, conductivity, and resistance to deformation, our CNTs LLDPE Masterbatch is perfect for manufacturers looking to elevate the performance of their polymer products.

Key factor

Uniform Dispersion: Advanced manufacturing processes ensure the CNTs are uniformly dispersed within the LLDPE matrix, maximizing performance enhancements.

Versatile Application Range: Can be used in film blowing, injection molding, and extrusion processes, among others.

Customizable Concentrations: Available in various CNT concentrations to meet specific application requirements.

Environmental Resistance: Offers improved barrier properties and resistance to UV radiation, chemicals, and moisture.

Applications

Packaging Films: Ideal for producing high-strength, durable packaging materials with enhanced barrier properties.

Automotive Components: Used in manufacturing lightweight, durable automotive parts that require high performance and reliability.

Electrical and Electronics: Suitable for creating ESD-safe containers, housings, and other components requiring electrical conductivity.

Industrial Products: Enhances industrial containers, pipes, and sheets, offering superior durability and resistance to harsh environments.

Advantages

Enhanced Mechanical Properties: Improves strength, stiffness, and resistance to wear, extending the lifespan of final products.

Improved Thermal Stability: Increases the heat deflection temperature, making it suitable for applications requiring high thermal resistance.

Electrical Conductivity: Introduces electrical conductivity to LLDPE products, opening up new applications in electrostatic discharge (ESD) protection and conductive components.

Ease of Processing: Masterbatch format ensures seamless integration into existing LLDPE processing lines without the need for significant modifications.

References

- Influence of blending protocol on the thermal and electrical properties of HDPE/LLDPE/CNT nanocomposites, CM Santos, TLA Montanheiro, EH Backes… - AIP Conference …, 2016 - pubs.aip.org

- Dispersion of carbon nanotubes into polyethylene by an additive assisted one-step melt mixing approach, MT Müller, P Pötschke, B Voit - Polymer, 2015 - Elsevier

- Effect of Masterbatch Type and Concentration on Carbon Nanotube Reinforced Polyolefin Blend Nanocomposites, B Moussa - 2018 - prism.ucalgary.ca