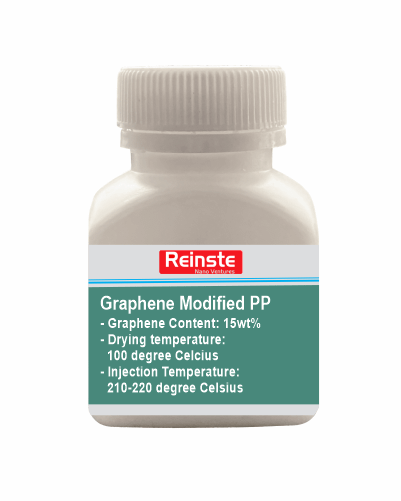

Product Overview

Our PP (Polypropylene) Graphene-Modified product marks a significant advancement in polymer technology, combining the lightweight, versatile characteristics of polypropylene with the exceptional strength, thermal, and electrical properties of graphene. This innovative composite material is engineered for applications requiring improved performance, offering a sustainable and efficient solution across a broad range of industries.

Key factor

- Superior Strength: Incorporating graphene significantly enhances the tensile strength and durability of polypropylene, making it ideal for high-strength applications.

- Improved Thermal Conductivity: Enhanced heat distribution properties allow for better thermal management in applications where heat resistance is crucial.

- Increased Electrical Conductivity: The typically insulating polypropylene gains conductivity with graphene modification, opening up new uses in electrical and electronic applications.

- Chemical Resistance: Maintains polypropylene’s inherent resistance to chemicals, with added graphene for improved barrier properties.

- Sustainability: Offers an eco-friendly alternative to conventional materials, supporting sustainability in manufacturing and product lifecycle.

Applications

- Enhanced Performance: Delivers a balance of strength, durability, and conductivity, surpassing traditional PP in demanding environments.

- Versatility in Applications: Suitable for a wide array of uses, from automotive components to electronic packaging and industrial goods.

- Improved Product Lifespan: The durability conferred by graphene extends the life of products, contributing to cost savings and environmental sustainability.

- Ease of Processing: Compatible with existing polypropylene processing methods, ensuring seamless integration into manufacturing workflows.

Advantages

- Automotive Parts: Used in the production of lightweight, durable components that contribute to vehicle efficiency and safety.

- Packaging Solutions: Ideal for creating robust, conductive packaging materials for sensitive electronic goods.

- Consumer Products: Enhances everyday items with increased strength and durability, from household appliances to recreational goods.

- Industrial Manufacturing: Applied in machinery parts and containers that benefit from enhanced material properties, including conductivity and thermal stability.

Why HIYKA

Graphene-Modified Polypropylene redefines the capabilities of conventional PP, offering a material solution that combines performance with sustainability. Whether for advanced automotive engineering, durable consumer products, or innovative industrial applications, our graphene-modified PP sets new standards for excellence and versatility in material science. Embrace the future of polymers with our cutting-edge solution, where unparalleled performance meets eco-friendly innovation.