Indium nanoparticle application:

- Indium nanoparticles used in electronic slurry for semiconductor, alloy with high purity and silicon solar cells. It can reduce temperature of sintering.

- In nanopowder added into welding alloy in order to lower the melting point of the alloy and increase wear resistance of alloy.

- If indium nanoparticle used in lubricant oil, the wear resistance of lubricant oil will increase.

- Indium nanoparticles can also be used as combustion improver for rocket fuel.

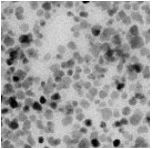

- Nano-indium powder, high purity, particle size uniform, easily dispersed, high surface activity, can be used in the semiconductor, high purity alloys and silicon solar cell back field aluminum paste (paste, aluminum paste, etc.), antistatic materials and other aspects;

- Nanometer indium powder can be used as transparent antistatic coatings and surface materials were using additives;

- Nano-indium powder has anti-static, transparency and excellent abrasion and scratch performance, is a new generation of electronic packaging materials, flat panel display platform, clean indoor surfaces such as the ideal material to add material;

- Nano indium material also has conductive properties; this feature also makes it possible to be the future of photovoltaic cells (solar cells), medical equipment and materials excellent imaging products of biotechnology.

- Electronic slurry, lower the sintering temperature of electronic paste;

- For welding alloys, lower the melting point of the alloy;

- Used in alloys, improve the wear resistance of the alloy;

- For lubricating oil, improve the wear lubricants performance;

- Application coatings, improve transparency and abrasion resistance, scratch resistance, electrical conductivity and other capabilities;

Storage:

Damp reunion will affect its dispersion performance and using effects, this product should be sealed in vacuum and stored in cool and dry room and it should not be exposure to air and should be avoided under stress.