Product Overview

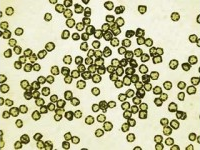

Nano silicon dioxide, also known as nano SiO2, is a form of silicon dioxide engineered at a nanometric scale. This material is renowned for its high surface area, exceptional purity, and unique physical and chemical properties, which make it a vital component in various high-performance coatings. Nano SiO2 is widely utilized in industries such as automotive, electronics, construction, and healthcare due to its ability to enhance durability, functionality, and efficiency of products.

Key factor

- Particle Size and Distribution: Nano SiO2 particles typically range from 10 to 40 nanometers in diameter, ensuring a high surface area for better interaction with the coating matrix.

- Purity and Quality: High purity levels minimize the risk of impurities affecting the coating’s properties and performance.

- Dispersion Stability: Effective dispersion in the coating solution is crucial for achieving uniform distribution of nano SiO2 particles, enhancing the coating's overall performance.

- Compatibility with Coating Polymers: Nano SiO2 must be compatible with various polymers and solvents used in coatings to ensure optimal performance and stability.

Applications

- Automotive Coatings: Used to enhance the durability and weather resistance of automotive paints.

- Protective Coatings: Applied in anti-corrosion and anti-scratch coatings in construction and heavy industries.

- Electronic Coatings: Utilized in coatings for electronic devices to provide moisture and thermal protection.

- Optical Coatings: Critical in anti-reflective coatings on lenses and other optical components.

- Medical Coatings: Helps in creating antimicrobial and biocompatible coatings for medical devices.

Advantages

- Enhanced Mechanical Properties: Incorporation of nano SiO2 improves scratch resistance, hardness, and wear resistance of coatings.

- Improved Durability: Nano SiO2 enhances UV resistance and chemical stability, extending the life of coatings under harsh environmental conditions.

- Increased Transparency: Nano SiO2 can be used in thin films and clear coatings without compromising transparency, ideal for protective and aesthetic purposes.

- Thermal Stability: It provides improved thermal stability, making it suitable for high-temperature applications.

- Cost-Effectiveness: Although advanced, nano SiO2 is cost-effective in the long run due to its durability and efficiency enhancements.

Why HIYKA

Nano SiO2 is chosen for its ability to meet the demanding requirements of modern coating applications. Its versatility and effectiveness in enhancing the physical properties of coatings, coupled with its adaptability across various industries, make it an indispensable material. The technological advancements in nanotechnology further allow for continual improvements in nano SiO2 production, making it more efficient and accessible for industrial applications.