Tin Nanoparticles Supplier, Tin NanoparticlesDealer, Tin NanoparticlesDistributor, Tin Nanoparticles India, Tin Nanoparticles Manufacturer, Tin Nanoparticles , Tin Nanoparticles Solution, Tin Nanoparticles Research grade, Tin Nanoparticles Industrial, Tin Nanoparticles Commercial, Tin Nanoparticles

Tin Nanoparticles Supplier, Tin Nanoparticles Dealer, Tin Nanoparticles Distributor, Tin Nanoparticles India, Tin Nanoparticles Manufacturer, Tin Nanoparticles Powder, Tin Nanoparticles Solution, Tin Nanoparticles Research grade, Tin Nanoparticles Industrial, Tin Nanoparticles Commercial, Tin Nanoparticles

Tin Nanoparticles Supplier, Tin NanoparticlesDealer, Tin Nanoparticles Distributor, Superfine Crystalline Boron Nano particles India, Tin Nanoparticles Manufacturer, Tin Nanoparticles Powder, Tin NanoparticlesSolution, Tin Nanoparticles Research grade, Ultra Fine Tin Nanoparticles Industrial, Tin Nanoparticles Commercial, Tin Nanoparticles

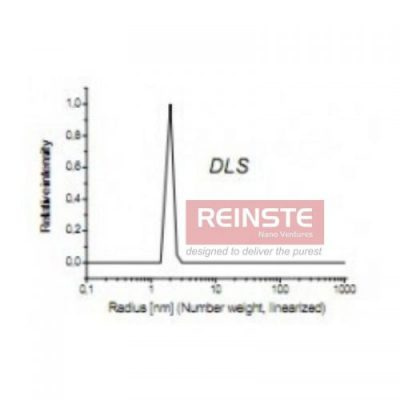

Tin Nanoparticles, 70nm,100nm,150nm

| Particle size | 70nm(RN-HW-A192), 100nm (RN-HW-A195), 130nm (RN-HW-B198 ) |

| Purity CAS No HS code | 99.9% 7440-31-5 8007009000 |

| Shape | Black Spherical Powder |

Nano tin powder in no-clean solder soft fiber, powder metallurgy, metal paste, porous self-lubricating bronze bearings, plasma spraying in the field of raw materials, rubber and plastics additives, lubricity additives, organic tin and other raw materials has broad application prospects, in metallurgy, chemical industry, electronics, defense, aerospace and other research showing a very important value.

Tin is malleable strong, rust resistant, low melting point, chemical stability and other excellent properties, which is widely used in food packaging, electroplating, metallurgy and other industries. Tin of special alloys, such as Babbitt alloys, solder, zirconium-based alloys, titanium-based alloys is atomic energy, aerospace, shipbuilding, medical, electronic and other industries indispensable raw materials. Tin compounds play an important role in the ceramics, printing, plastics, agriculture and other industries.

Application:

1.Metal Nano lubrication additive: add 0.1~1% Nano tin powder into lubricating oil and lubricating grease. Make the friction in the process of the friction surface self-lubricating, self-healing membrane, significantly reduce the friction pair antiwear and antifriction performance.

2.Activated sintering additives: Nano tin substantially reduces powder metallurgy product and high temperature ceramic sintering temperature of the product in the powder metallurgy.

3.The surface of the metal and the metalloid conductive coating processing: under the anaerobic conditions, below the temperature of melting point to implement microelectronic device coating.

4.Metal Nano lubrication additive .

5.Activated sintering additives.

6.The surface of the metal and the metalloid conductive coating processing.

7. Nano tin powder used in pharmaceutical, chemical, light industry, food, health care, art supplies, and other areas of the packaging due to its avirulent environmental protection characteristic.

Disclaimer

The product image(s) shown is a reference for the actual product. While every effort has been made to maintain complete accuracy and up to date product information, it is important to go through details such as product labels, manufacturing details, batch, warnings, and directions before using a packaged product.

For additional information, please refer to the contact details mentioned on the label.

For bulk orders contact us on [email protected]