Additive for electrical conductive coatings (ECOS HC) with excellent brilliance on polymers, glass and ceramic.

Additive for electrical conductive coatings with excellent brilliance on polymers, glass and ceramic. Applications in transparent conductivity, electrostatic dissipation, IR/Radar/EMI-shielding, low-E, invisible wiring, electrical heating, etc.

DESCRIPTION

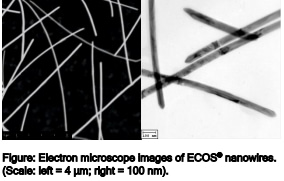

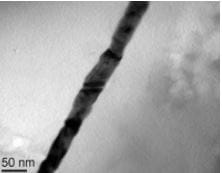

ECOS® HC is a stable viscous dispersion of silver nanowires in ethylene glycol, including stabilizing agents. Compatible with water and alcohol based inks and coating formulations. Spreading highly conductive ECOS® nanowires on surfaces gives control over surface resistance in a wide range while light transmission is almost unaffected. ECOS® nanowires form a percolating, two dimensional conductive network with interconnecting silver wires.

ECOS® HC is recommended for the preparation of own inks or coating formulations that have to be electrical conductive and may not be black or opaque. For outstanding electrical conductivity at highest transparency and low haze the addition of our surface activator SURFINK is recommended. For readymade transparent conductive coatings or inks other types of ECOS® are available.

TYPICAL APPLICATION AREAS

Transparent conductive electrodes. ECOS® HC is the ideal conductor for transparent electrodes in printed photovoltaic devices, displays, touch screens, OLED, luminescent devices and in switchable glasses. Compared to ITO coatings ECOS® electrodes are highly flexible and may be printed by a simple roll to roll process. Dissipative electrostatic discharge (ESD) applications. Transparent protection against ESD events for electronic devices and components.

- Explosion prevention. Low dirt adherence and contamination protection.

- Low-E coatings. ECOS® coatings reflect infrared (IR) radiation. Therefore, the application of ECOS® HC make optical attractive and energy saving low emissivity coatings accessible.

- Camouflage. Reflection properties of ECOS® allow tailor made IR and Radar camouflage coatings for textiles and hard surfaces.

- Electrical heating. Transparent or light colored electrically heatable coatings are feasible with ECOS® HC additives. Interesting applications range

from headlight lenses and windscreens to panel heating and heatable textiles. - Invisible wiring. ECOS® HC inks are applied in the invisible wiring of sensors, switches and lighting devices. These inks are printable and show much lower resistance than inks filled with the same amount of spherical silver particles.

FEATURES / BENEFITS

Transparent conductive coatings based on ECOS® HC typically reach sheet resistances of 10 Ohm/sq. at a light transmission of 90 %. 100 Ohm/sq.

coatings show light transmissions of up to 98 %. With ECOS® HC dissipative coatings with surface resistivities from 104 to 108 /sq. are achievable.

These coatings are compliant with DIN EN 61340-5- 1 and ATEX Directive 94/9/EC-II-2-GD.

ECOS® HC coatings can be applied by roll to roll printing processes, as well as by tampon or screen printing processes.

ECOS® HC coatings are highly reflective for IR and RADAR frequencies. Light colored textiles with outstanding camouflage and low-E properties are produced by dip & squeeze, screen or roll to roll printing processes. ECOS® nanowires are highly flexible. The application on flexible substrates like polymer films for flexible displays or flexible wiring is possible. ECOS® HC coated films or objects even can be thermoformed without loss in conductivity.

PRODUCT FORMS

Appearance: gray iridescent paste

Available container sizes: 1 kg, 5 kg, 25 kg

SPECIFICATIONS

Silver concentration 4,0 % wt

TYPICAL PROPERTIES

Water content < 1 %

Solvents Ethanediol

Colour gray

Mean silver wire diameter 50 nm

Mean silver wire length 25 µm

Stability, unopened (dark, cool storage)> 12 months

USE RECOMMENDATIONS

Miscibility: ECOS® HC can be diluted with water and short chain alcohol (2-Propanol, Ethanol) in any ratio. Please avoid the use of strong mechanical force and ultrasound dispersers during diluting ECOS® silver nanowires. ECOS® HC is not compatible with some organic solvents, especially acetone and ethyl acetate.

Additives: Ideally additives compatible with aqueous systems are used. The stability of the obtained nanowire dispersion should be controlled after the addition of additives. Coagulation or precipitations of solids should not occur within days and if so should be re-dispersible by shaking or gentle stirring.

Furthermore, the binder to silver content must be adjusted to avoid the formation of an insulation layer on the silver nanowire network.

SURFLINK:

SURFLINK is used as a surface activator in combination with ECOS® HC. SURFLINK improves the conductivity when used in combination with

ECOS® products. After mixing ECOS® products it is recommended to use the formulation fresh, at least within 24 hours to obtain the best possible results.

Curing:

After coating, curing temperatures in the range of 140 – 150°C are recommended (2 – 3 minutes). Temperatures below 140°C can cause a loose in

performance. Please avoid temperatures above 250°C.

Disclaimer

The product image(s) shown is a reference for the actual product. While every effort has been made to maintain complete accuracy and up to date product information, it is important to go through details such as product labels, manufacturing details, batch, warnings, and directions before using a packaged product.

For additional information, please refer to the contact details mentioned on the label.

For bulk orders contact us on [email protected]