Product Overview

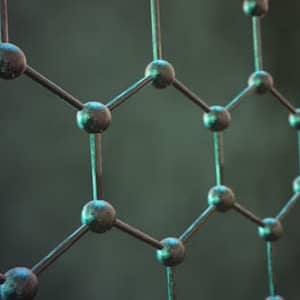

Unlock the potential of high-impact polystyrene (HIPS) with our advanced CNTs HIPS composite. This innovative material integrates the exceptional strength and conductivity of carbon nanotubes (CNTs) into the versatile and durable framework of HIPS. Designed for applications demanding high impact resistance, electrical conductivity, and thermal stability, our CNTs HIPS composite is an ideal choice for industries ranging from electronics to automotive and packaging. Experience the next level of material performance where innovation meets resilience.

Key factor

Uniform CNT Dispersion: State-of-the-art compounding techniques ensure a homogeneous distribution of CNTs, maximizing performance enhancements.

Versatile Processing: Compatible with standard HIPS processing equipment, facilitating easy adoption without significant operational changes.

Customizable Properties: Available in various grades to meet specific application requirements, including tailored electrical and mechanical properties.

Sustainable Material Choice: Provides a durable, high-performance alternative to more environmentally impactful materials.

Applications

Electronics Housing and Components: Ideal for producing robust, conductive casings and parts for electronic devices.

Automotive Parts: Enhances the performance of interior and exterior automotive components requiring high impact resistance and durability.

Packaging Solutions: Offers a high-strength, durable option for protective packaging, particularly for sensitive electronic goods.

Consumer Products: Suitable for a variety of consumer goods, including toys and household appliances, where durability and safety are paramount.

Advantages

Enhanced Impact Strength: Significantly increases the toughness of HIPS without compromising its ease of processing and surface finish.

Improved Electrical Conductivity: Introduces electrical conductivity to HIPS, making it suitable for electrostatic discharge (ESD) protection and electronic components.

Superior Thermal Stability: Elevates the material's resistance to thermal deformation, extending its applicability to high-temperature environments.

Environmental Resistance: Offers enhanced resistance to chemicals and UV radiation, ensuring longevity and durability in harsh conditions.

References

- Effect of multiwalled carbon nanotubes (MWNT) on the properties of high impact polystyrene (HIPS), J Li - Journal of Nanomaterials, 2018 - hindawi.com

- Polystyrene-based and carbon fabrİc-reİnforced polymer composİtes containing carbon nanotubes: preparation, modification and characterization, B Erkmen - 2020 - open.metu.edu.tr

- High Impact Polystyrene/CNT nanocomposites: Application of volume segregation strategy and behavior under extensional deformationM Marcourt, P Cassagnau, R Fulchiron, D Rousseaux… - Polymer, 2018 - Elsevier