Product Overview

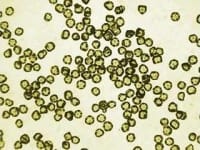

Hiyka's Our Grade 600/500 Diamonds represent the pinnacle of precision in abrasive materials. Carefully graded to ensure uniformity and consistency, these diamonds boast a particle size range of 500 to 600 µm (30-35 mesh), making them ideal for applications demanding meticulous attention to detail.Crafted with the highest standards of quality control, our diamonds guarantee sharp cutting edges and efficient material removal, enabling unparalleled performance in cutting, grinding, and polishing tasks.

Key factor

- Grade 600/500: Specifically graded diamonds for precision applications.

- Particle Size Range: Uniform particles ranging from 500 to 600 µm (30-35 mesh).

- High Purity: Produced with stringent quality control measures for consistent performance.

- Versatile: Suitable for various industrial applications demanding fine abrasives.

- Sharp Cutting Edges: Ensures efficient material removal and surface finishing.

Applications

- Precision Machining: Ideal for cutting, grinding, and shaping hard materials like ceramics, glass, and metals.

- Optics Manufacturing: Used in lens grinding and polishing for optical clarity and precision.

- Semiconductor Industry: Critical for wafer polishing and substrate preparation in semiconductor fabrication.

- Gemstone Processing: Facilitates the cutting and polishing of gemstones for jewelry and industrial applications.

- Aerospace and Automotive: Employed in the manufacturing of precision components and engine parts.

Advantages

- Precision Performance: Engineered for precise cutting, grinding, and polishing tasks.

- Enhanced Efficiency: Uniform particle size facilitates smooth and consistent material removal.

- Durability: Hard and resilient composition ensures longevity and repeated use.

- Reduced Downtime: Reliable performance minimizes interruptions, enhancing productivity.

- Cost-Effective: Optimal particle size distribution maximizes the utilization of abrasive material.

Why Choose Nano Diamonds

- Consistency: Ensures uniformity in the finished product, vital for precision applications.

- Optimized Performance: Tailored particle size range for specific tasks, enhancing efficiency.

- Reliability: Produced under strict quality standards to deliver consistent results.

- Versatility: Suitable for a wide range of industries and applications requiring fine abrasives.

- Cost Efficiency: Maximizes the utilization of abrasive material, reducing waste and costs.