Product Overview

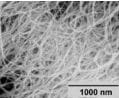

Graphene-Modified ABS leverages the groundbreaking properties of graphene to elevate the performance of traditional ABS plastic. This enhanced material combines the ease of processing and versatility of ABS with the exceptional strength, thermal conductivity, and electrical properties of graphene. Designed for applications demanding high performance and durability, Graphene-Modified ABS is a pioneering solution in automotive, electronics, and consumer goods manufacturing, offering superior mechanical properties and design flexibility.

Key factor

- Enhanced Mechanical Strength: The inclusion of graphene significantly improves the tensile strength, impact resistance, and durability of ABS, making it ideal for demanding applications.

- Improved Thermal Conductivity: Integrates graphene’s superior thermal properties, offering better heat dissipation for components that experience thermal stress.

- Electrical Conductivity: Adds electrical conductivity to the inherently insulating ABS, opening up new applications in electrostatic discharge (ESD) protection and electronic components.

- Versatile Processing: Maintains the easy processing characteristics of ABS, compatible with standard manufacturing processes such as injection molding and 3D printing.

Applications

- Broad Application Potential: From automotive components to electronic housings and consumer products, graphene-modified ABS is versatile for various high-performance applications.

- Increased Durability: Products made from graphene-modified ABS exhibit enhanced longevity and wear resistance, reducing the need for replacements and maintenance.

- Enhanced Safety: The material's improved flame retardancy and ESD protection contribute to safer applications in electrical and electronic products.

- Cost-Efficiency: Despite its advanced properties, graphene-modified ABS can be processed using conventional techniques, keeping production costs in check.

Advantages

- Automotive Components: Ideal for interior and exterior parts requiring enhanced strength, thermal stability, and aesthetic appeal.

- Electronics and Electrical Housings: Suitable for enclosures and components that benefit from improved heat dissipation and electrical conductivity.

- Consumer Products: Enhances the performance and durability of household appliances, sporting goods, and toys with advanced material properties.

- Industrial Applications: Utilized in creating machinery parts, tools, and fixtures that demand high strength and resistance to wear and environmental factors.

Why HIYKA

Graphene-Modified ABS is a transformative material solution that bridges the gap between traditional polymers and advanced composite materials. By harnessing the unique benefits of graphene within the versatile matrix of ABS, it unlocks new possibilities in design and functionality across multiple industries. Embrace the innovation of graphene-modified ABS in your products to achieve unmatched performance, durability, and efficiency, driving forward the future of material science and manufacturing.