Product Overview

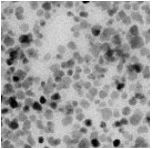

Zirconium Diboride (ZrB2) Nanopowder is a ceramic material renowned for its exceptional properties at high temperatures. This material is available in various particle sizes, including ultrafine nanoparticles and larger microparticles, providing flexibility in application and fabrication techniques. ZrB2 is utilized primarily in environments where extreme heat, abrasion, and corrosive conditions are prevalent.

Key factor

- Particle Sizes: Available in a range of sizes from 100 nm to 5 µm, catering to diverse application needs.

- High Purity: Zirconium Diboride (ZrB2) is known for its high purity and consistency.

- High Melting Point: Withstands extremely high temperatures, making it suitable for high-temperature applications.

- Excellent Hardness and Strength: Exhibits superior hardness and mechanical strength.

- Thermal and Electrical Conductivity: Offers good thermal and electrical conductivity properties.

Applications

- Aerospace: Components such as nose tips, leading edges, and other parts of spacecraft and hypersonic vehicles.

- Defensive Armor: Used in armor plating due to its hardness and thermal shock resistance.

- Cutting Tools: Ideal for high-performance cutting tools that operate under high thermal and mechanical stress.

- Nuclear Industries: Components that require high thermal neutron absorption.

- Thermal Management Systems: Used in systems requiring efficient heat dissipation.

Advantages

- High-Temperature Stability: Maintains structural integrity and performance at temperatures up to 3245°C.

- Abrasion Resistance: Offers excellent resistance to wear and tear, suitable for abrasive environments.

- Corrosion Resistance: Highly resistant to chemical attack, even at high temperatures.

- Versatility in Processing: Can be processed in various forms, including sintering, pressing, and deposition.

- Enhanced Composite Performance: When mixed with other ceramic or metallic materials, it enhances the overall mechanical and thermal properties of the composite.

Why HIYKA

Optimized for extreme environments, ensuring longevity and reliability. Offers versatility for different industrial applications and fabrication techniques. Consistently produced to meet rigorous quality standards. Provides cutting-edge solutions for industries demanding high-performance materials.