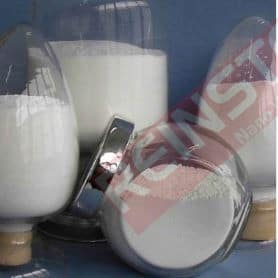

Product Overview

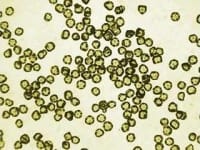

The Zirconium Oxide 3Y Tetragonal phase is engineered for superior performance, providing a robust solution for high-stress applications. Recognized for its high-performance ZrO2 ceramics properties, this material is ideal for industries demanding the utmost in mechanical strength and thermal stability.

Key factor

- Exceptional Mechanical Strength: The tetragonal phase of ZrO2 maximizes toughness and prevents crack propagation, essential for applications that require high mechanical reliability.

- Enhanced Thermal Stability: This form of Zirconium Oxide maintains excellent properties under high temperatures, resisting thermal shock and ensuring performance stability in extreme environments, marking it a leader in thermal stability in Zirconium Oxide.

- Increased Wear Resistance: Known for its wear-resistant Zirconium Oxide properties, it provides excellent wear resistance, extending the service life of components subject to high wear conditions.

- Chemical Durability: Maintains performance integrity in corrosive environments, resisting reactions with acids and bases.

- Dimensional Stability: Ensures minimal dimensional changes under temperature fluctuations, preserving the accuracy and fit of components.

Applications

- Industrial Machinery: A prime example of advanced ceramics for industrial applications, it is ideal for producing components that are exposed to mechanical wear and high temperatures, such as gears and bearings.

- Medical Devices: As a material used in ZrO2 3Y for medical devices, it is utilized in the manufacturing of dental and orthopedic implants that require high strength and biocompatibility.

- Automotive and Aerospace: Enhances the durability and performance of critical components such as turbine blades and engine parts.

- Electronics: Applied in the creation of substrates and other components that benefit from high thermal conductivity and insulation properties.

Advantages

- Extended Component Lifespan: The robust properties of ZrO2 3Y reduce the need for frequent replacements, offering long-term reliability.

- Adaptability in Design: Can be engineered to meet specific design and performance requirements across a broad range of industries.

- High-Performance Under Stress: Particularly suited to applications involving high mechanical and thermal stress.

- Cost Efficiency: Though premium in performance, it remains cost-effective over the lifecycle due to its durability and minimal maintenance needs.

- Environmentally Friendly: Produced with processes aimed at minimizing environmental impact.

Why HIYKA

Hiyka is a leader in the field of advanced ceramics, providing Zirconium Oxide in the 3Y tetragonal phase with unmatched quality and customization options. Our cutting-edge manufacturing processes ensure each batch of ZrO2 meets rigorous standards for purity and performance. Supported by a global network of experts and facilities, Hiyka offers comprehensive solutions, from material selection to post-deployment support, ensuring that our clients achieve optimum results with their projects.