Product Overview

Nano-silica surface is a layer of silicone and even silanol groups, these groups have a strong absorption capacity. Silanol susceptible to chemical reaction, so that the nanometer silica surface modified more easily. These special structural and physico chemical properties, the nano silica has excellent acid, alkali, high temperature and electrical insulation, absorption, dispersion, thickening, thixotropic and cut light resistance and other properties.

Key factor

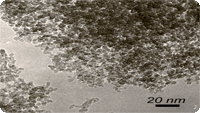

- Nano sio2 nano materials as an important member of its surface with a hydroxyl group, is ultra-fine powder, particle size <100nm, usually 20-30nm, high chemical purity, good dispersion, high specific surface area.

- In the chemical industry, also known as silica, it is the highest yield of a nano-powder material is currently the world’s large-scale industrial production.

- Its products are widely used in electronic packaging materials, the field of polymer composite materials, plastics, paints, rubber, paints, ceramics, adhesives, glass, steel, pharmaceutical carriers, cosmetics and antibacterial materials.

Applications

- Fiber reinforced composite: The oily silica nanoparticles fully and evenly dispersed in the resin material, can fully improve the resin base material performance. Can improve the strength and elongation, abrasion resistance and material surface finish, anti-aging performance.

- Pigment: Nano silica can improve oily coating suspended, poor stability of thixotropy, weather resistance and washing resistance, make the coating combined with wall strength greatly increased, increased the coating hardness, improves surface self-cleaning ability.

- Ceramic: Si02 can instead of nano A1203 , can improve the strength, toughness and hardness of ceramic materials and properties, such as elastic modulus,using nano Si02 composite ceramic substrate can improves the density of the substrate, toughness and degree of finish, sharply lower sintering temperature.

Advantages

- Heat resistance: Due to a large specific surface area of nano silica particles, the interfacial adhesion effect and epoxy matrix is strong, absorb large amounts of impact energy, but also increases the rigidity of the matrix, and therefore within the scope of certain nano silica particles toughening epoxy resin, but also improve the heat resistance of materials.

- Toughening effect: due to the addition of nano silica particles, impact strength epoxy composites, tensile strength, elongation and other properties within a certain range has improved greatly, indicating that nano-silica toughening particles played a role. It highlights the nanoscale silica excellent filling properties, and the material performance has been greatly improved.

Why HIYKA

Hiyka's nano silica particles are engineered to integrate seamlessly into epoxy resins and superhydrophobic coatings. These nanoparticles significantly improve the mechanical properties of epoxy resins, including increased tensile strength and enhanced abrasion resistance. In superhydrophobic coatings, our nano silica enhances water repellency, ensuring that surfaces stay dry and clean longer.