Product Overview

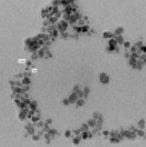

Hiyka's Graphitized Hydroxy Multi-Walled Carbon Nanotubes represent a cutting-edge advancement in carbon nanotechnology, engineered to meet the demanding requirements of modern material science and engineering. These MWCNTs undergo a specialized graphitization process to enhance their electrical and thermal conductivity, while the introduction of hydroxy (-OH) groups on their surface significantly improves their solubility and chemical reactivity. Ideal for applications in advanced composites, energy storage, electronics, and catalysis, our graphitized hydroxy MWCNTs offer a unique combination of properties that drive innovation and performance.

Key factor

Superior Electrical and Thermal Conductivity: The graphitization process enhances the intrinsic conductivity of MWCNTs, making them suitable for high-performance electronic and thermal management applications.

Improved Dispersion and Solubility: Hydroxy functionalization increases the compatibility of MWCNTs with a variety of solvents and polymer matrices, enabling easier processing and integration.

Enhanced Chemical Reactivity: The presence of hydroxy groups facilitates further chemical modifications, expanding the range of potential applications.

Exceptional Mechanical Properties: Maintains the high tensile strength and durability characteristic of carbon nanotubes, reinforcing the performance of composite materials.

Versatile Application Potential: From reinforcing polymers to conducting electricity and heat, these MWCNTs are adaptable to a wide range of uses.

Applications

Advanced Composite Materials: Enhances the mechanical, electrical, and thermal properties of polymers and resins for automotive, aerospace, and electronics industries.

Energy Storage Devices: Improves the efficiency and capacity of batteries and supercapacitors, leveraging enhanced conductivity and electron transfer rates.

Electronics and Conductive Inks: Key for developing conductive pathways in flexible electronics and high-performance circuits.

Catalysis and Environmental Remediation: Utilized in catalytic processes and environmental sensors, benefiting from enhanced surface reactivity and conductivity.

Biomedical Applications: Explored for use in drug delivery systems and tissue engineering, leveraging biocompatibility and functionalization capabilities.

Advantages

- High-Performance Material: Delivers exceptional improvements in conductivity, mechanical strength, and thermal stability, driving forward technological advancements.

- Chemical Versatility: Hydroxy groups enable further functionalization, allowing for tailored interactions with various chemicals and substrates.

- Sustainable Solution: Offers a durable and effective alternative to traditional materials, supporting green technology initiatives.

- High-Quality Manufacturing: Produced under strict quality control standards to ensure purity, uniformity, and consistency across batches.

- Scalable for Industrial Use: Available in bulk quantities to meet the needs of large-scale manufacturing and application without compromising quality.

References

- Evaluation of mild acid oxidation treatments for MWCNT functionalizationF Avilés, JV Cauich-Rodríguez, L Moo-Tah, A May-Pat… - Carbon, 2009 - Elsevier.

- Oxidation and reduction of multiwalled carbon nanotubes—preparation and characterizationB Scheibe, E Borowiak-Palen, RJ Kalenczuk - Materials Characterization, 2010 - Elsevier.

- Highly sensitive detection of multiple antiviral drugs using graphitized hydroxylated multi-walled carbon nanotubes/ionic liquids-based electrochemical sensorsZ Zhang, H Zheng, Y Liu, S Ma, Q Feng, J Qu… - Environmental …, 2024 - Elsevier.